Renobuild synthetic resin floors offer durable solution for surfaces that are exposed to specific loads in different industries : heavy loads , chemicals, heavy traffic , electrostatic charges , slippery floors , etc.

Each situation is different and requires a bespoke technical analysis.

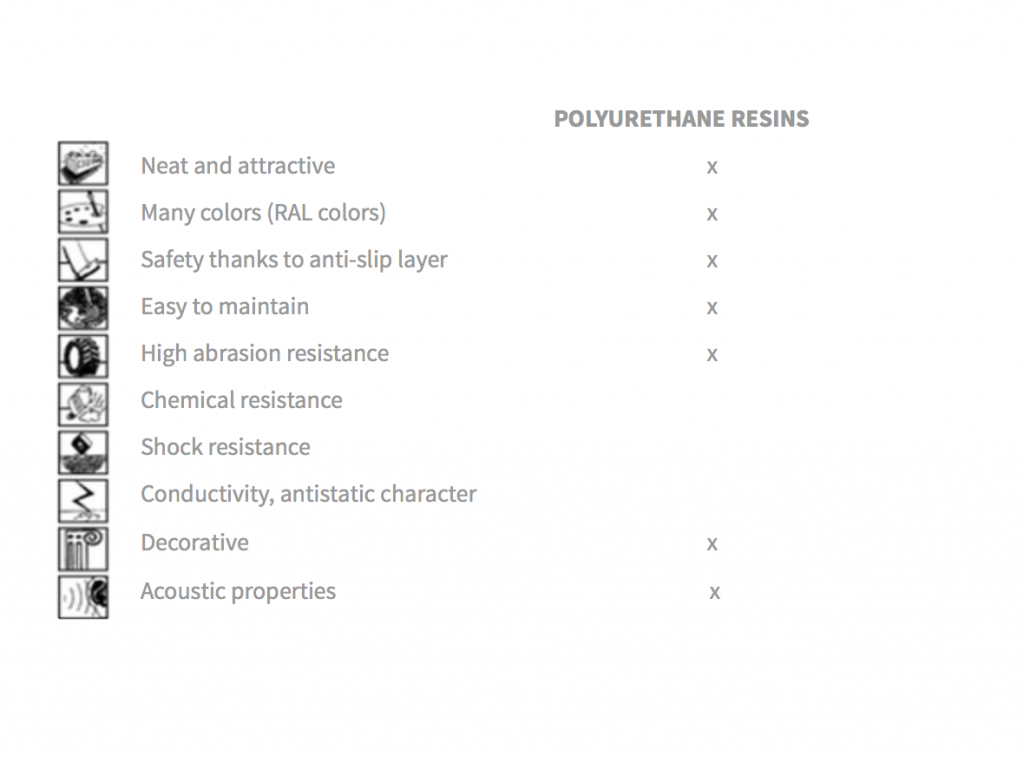

polyurethane resin

Factsheet

Polyurethane resins commonly known as “pu” are self-leveling coatings most often applied in the Tertiary sector, but also sometimes in the industry when the operating constraints or aesthetic requirements are compatible.

These resin coatings are more aesthetic ( less sensitive to scratches ) , decorative, and even acoustic with some systems.

They are applicable to many types of different substrates: concrete, screed , tiles, asphalt mixes.

Each type of substrate requires specific preparation that we provide with professional equipment consisting of shot blasting machines, planers, sanders, industrial vacuum cleaners to ensure optimum strength of the coating over time.

Renobuild advises you every step of your project and helps you choose the best technical and economical solution.

Process

Substrate Preparation.

Application of the primary layer.

Application of the self-leveling layer.

Application of the topcoats.

> RENOBUILD.BE

> RENOBUILD.BE